home

back

EuroPi for AE modular

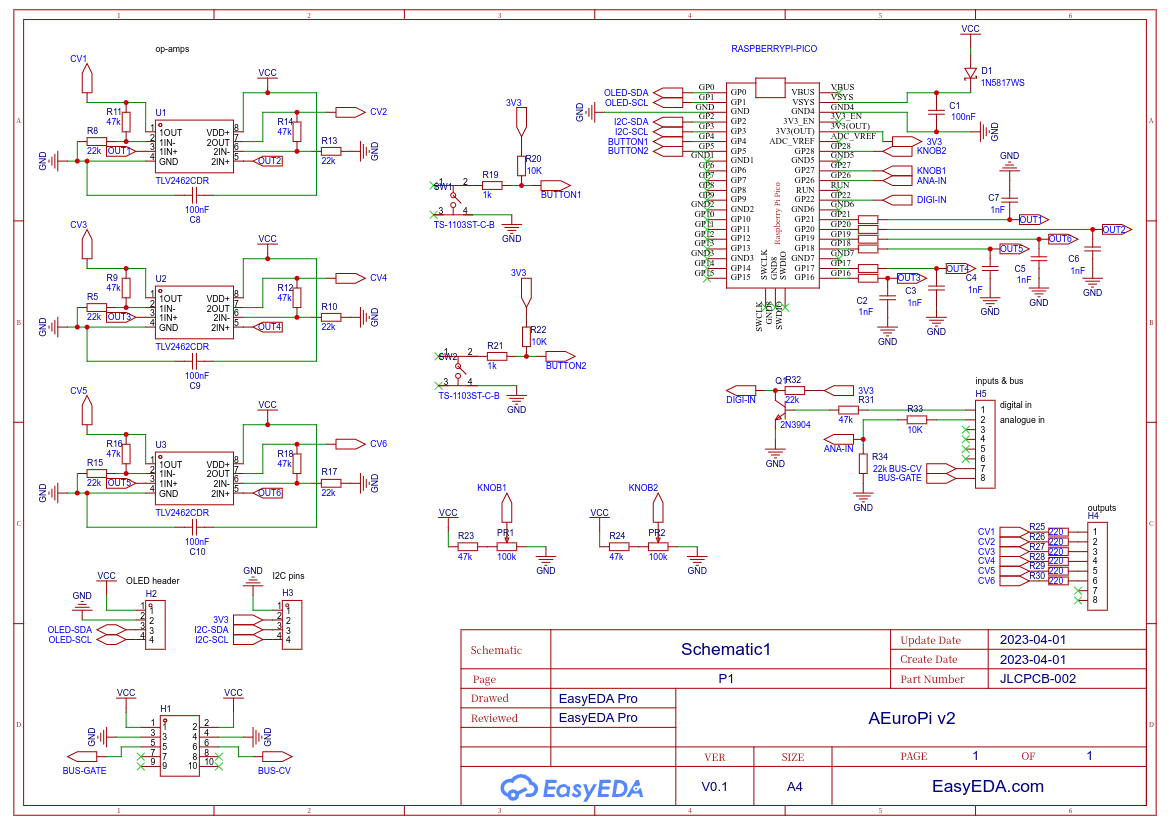

inspired by this forum post and the open-source EuroPi design by Allen Synthesis

the main goals:

- hardware adjustments to meet the AE 0-5v standard

- any additional software adjustments to meet the same

- squeeze everything into an AE format 2U module (100x50mm, 25mm depth)

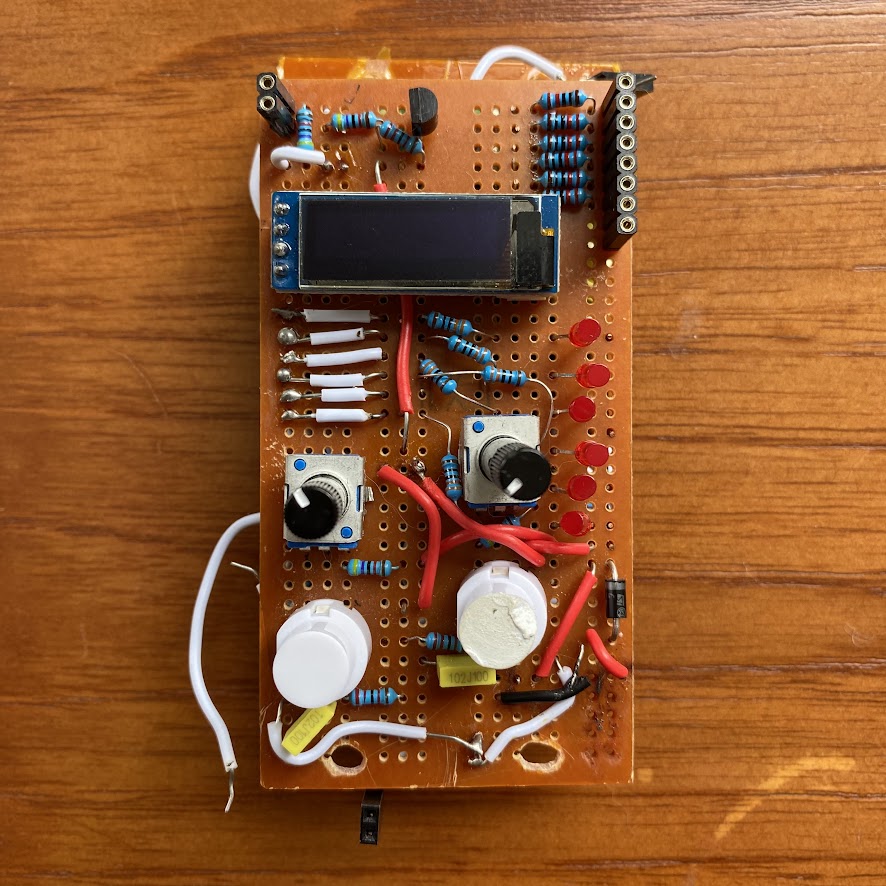

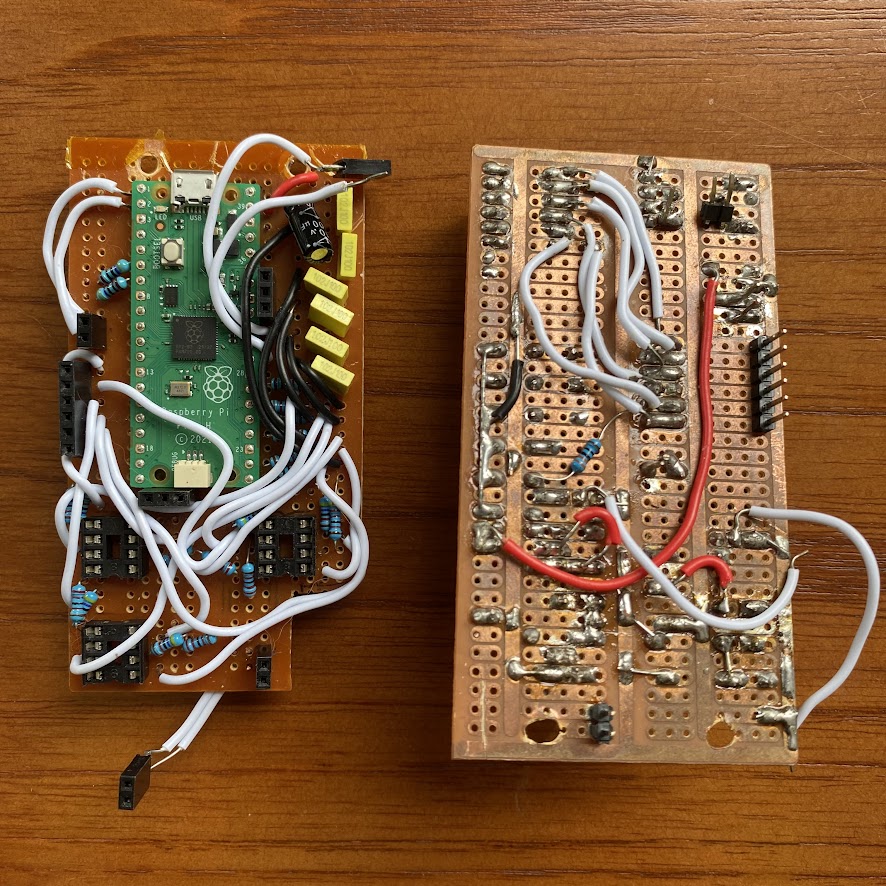

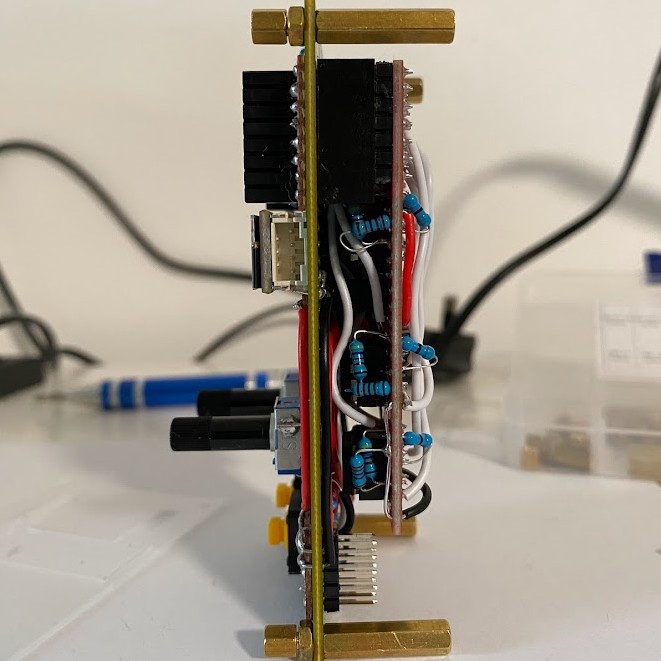

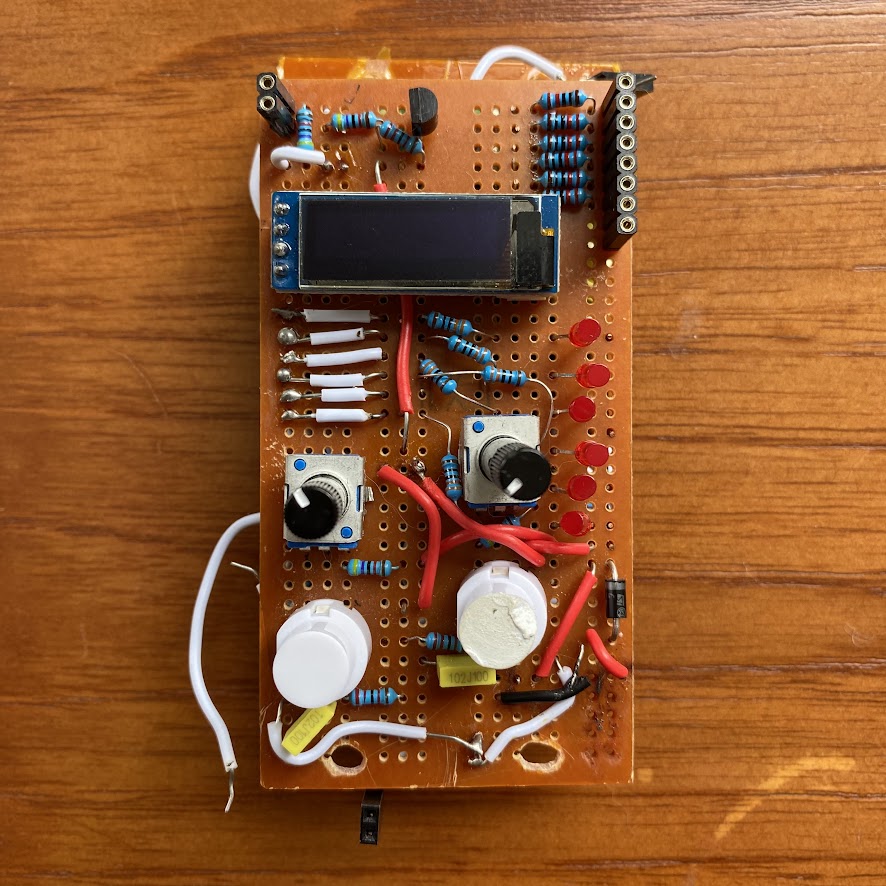

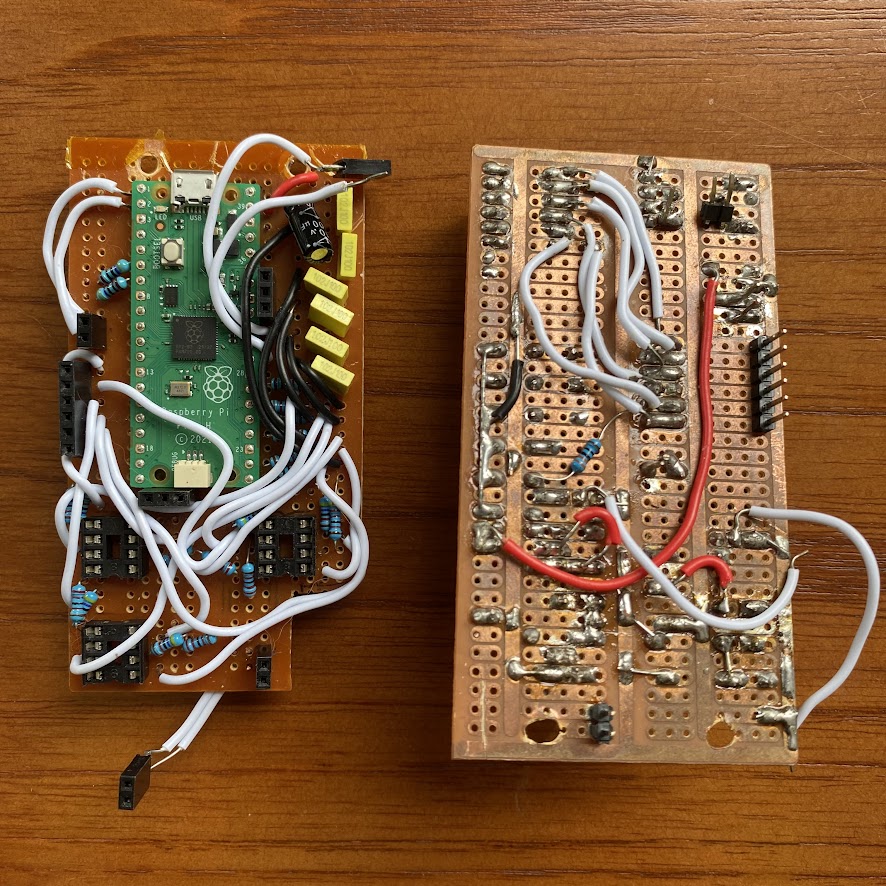

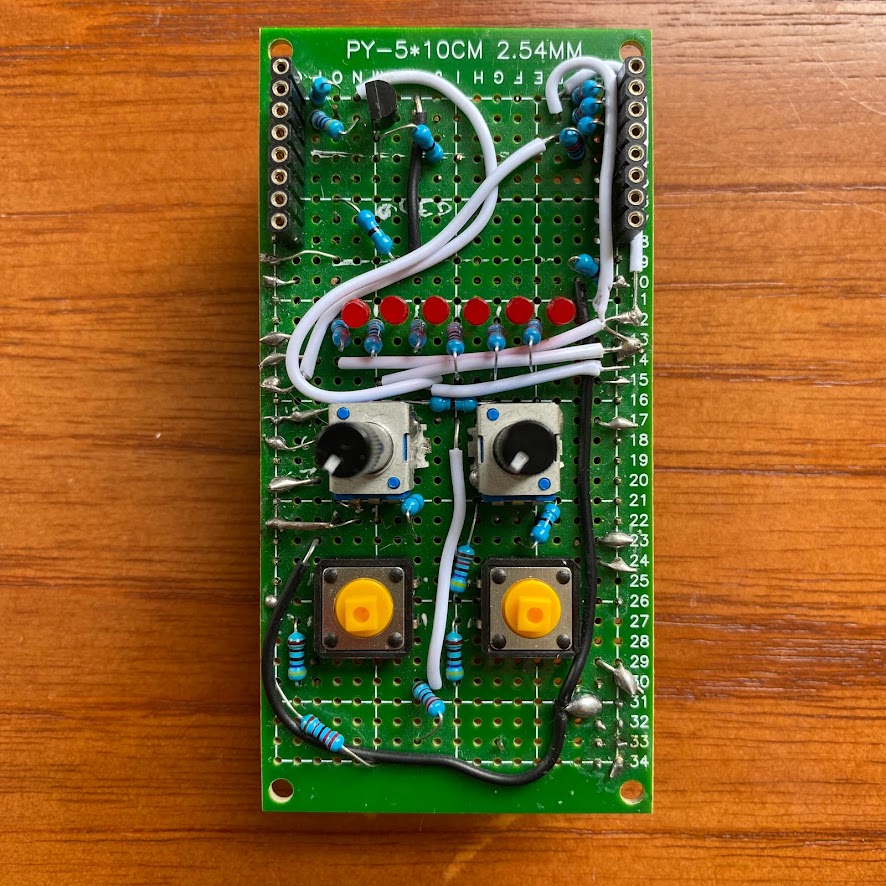

first prototype

hand-soldered, manually wired on two layers of stripboard to form a sandwich

working:

- screen

- op-amps

- outputs in 0-5v range

- buttons

not working:

- knobs

- outputs are in the wrong order

- digital input not reliable

- analogue input permanently offset

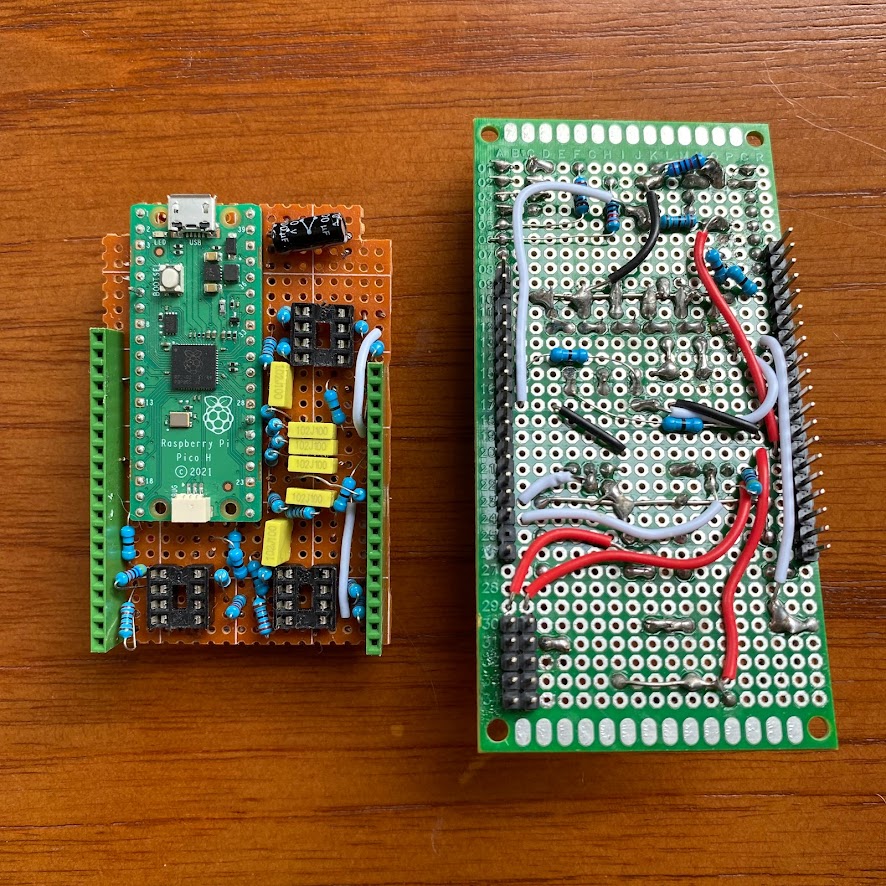

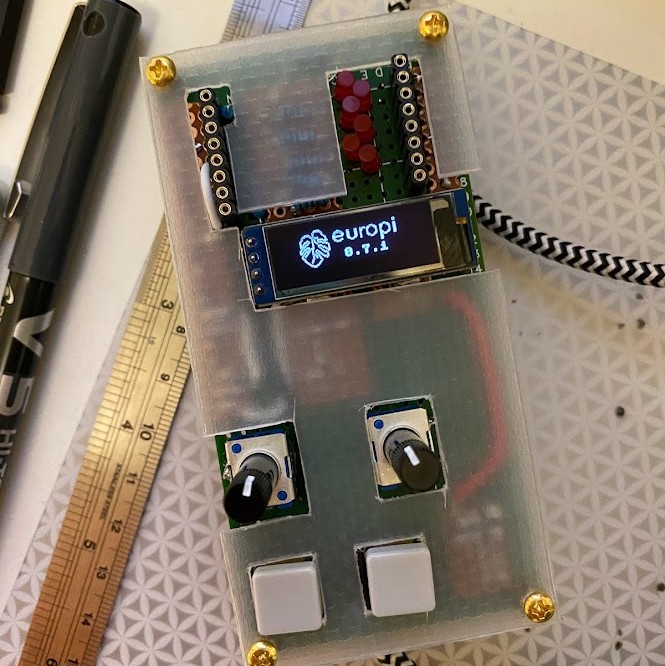

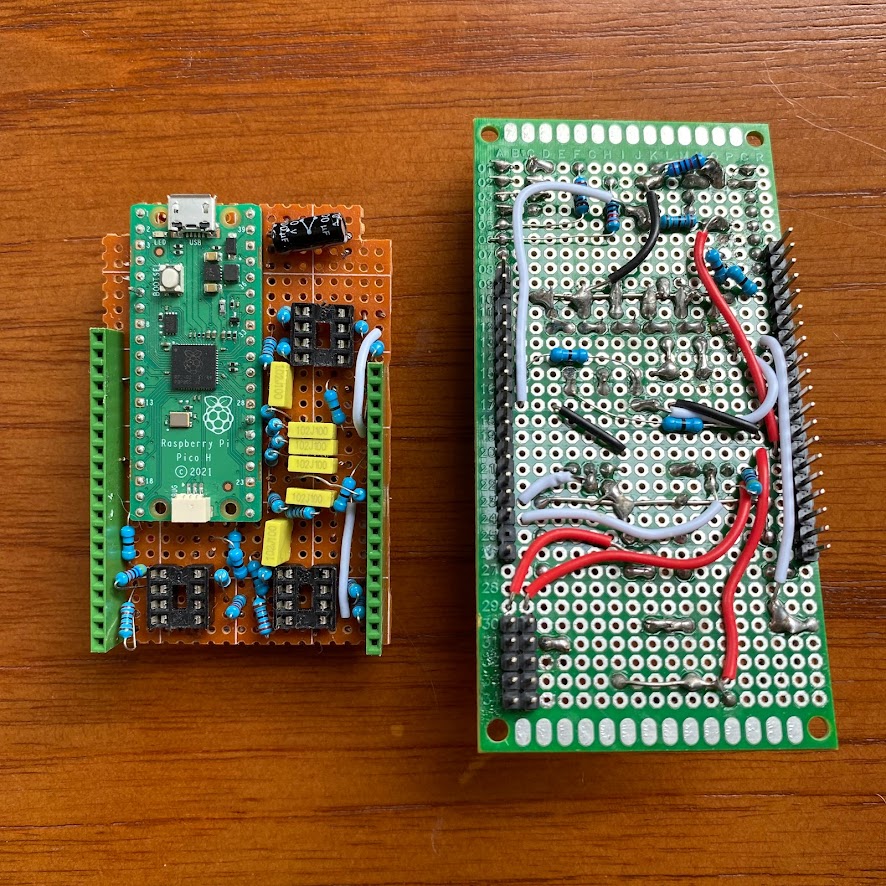

second prototype

better-quality board, correct dimensions, slightly more sensible wiring layout. accidentally killed the pico while trying to make some changes... it was going well until then.

still causing problems:

- leds

- analogue input slight offset

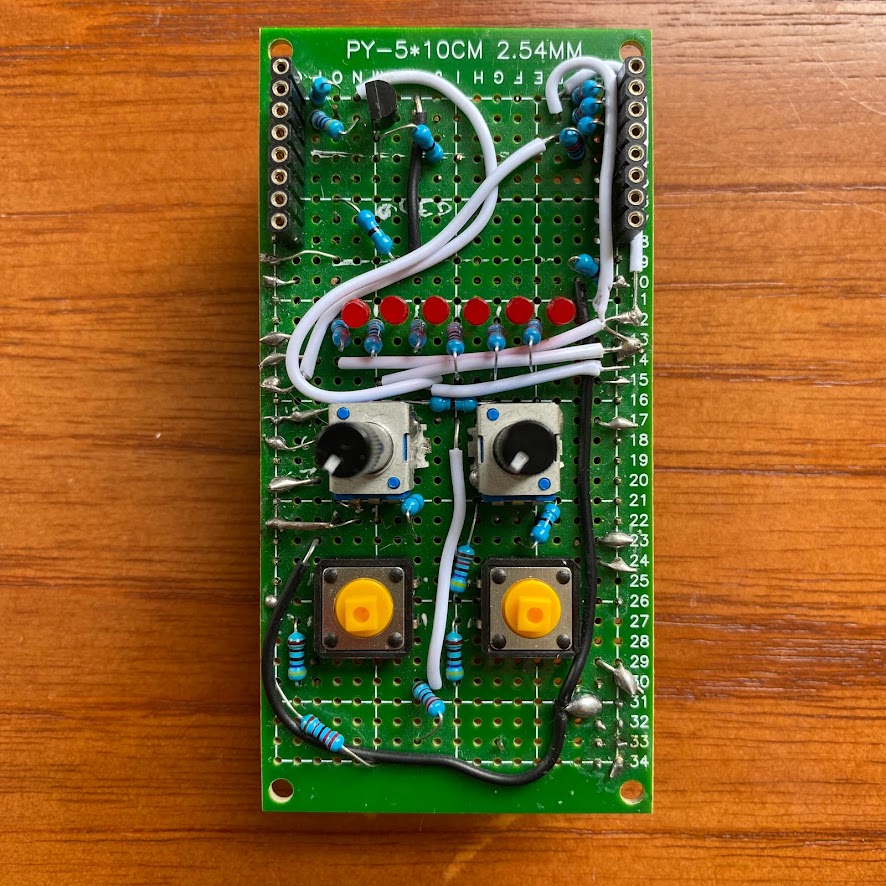

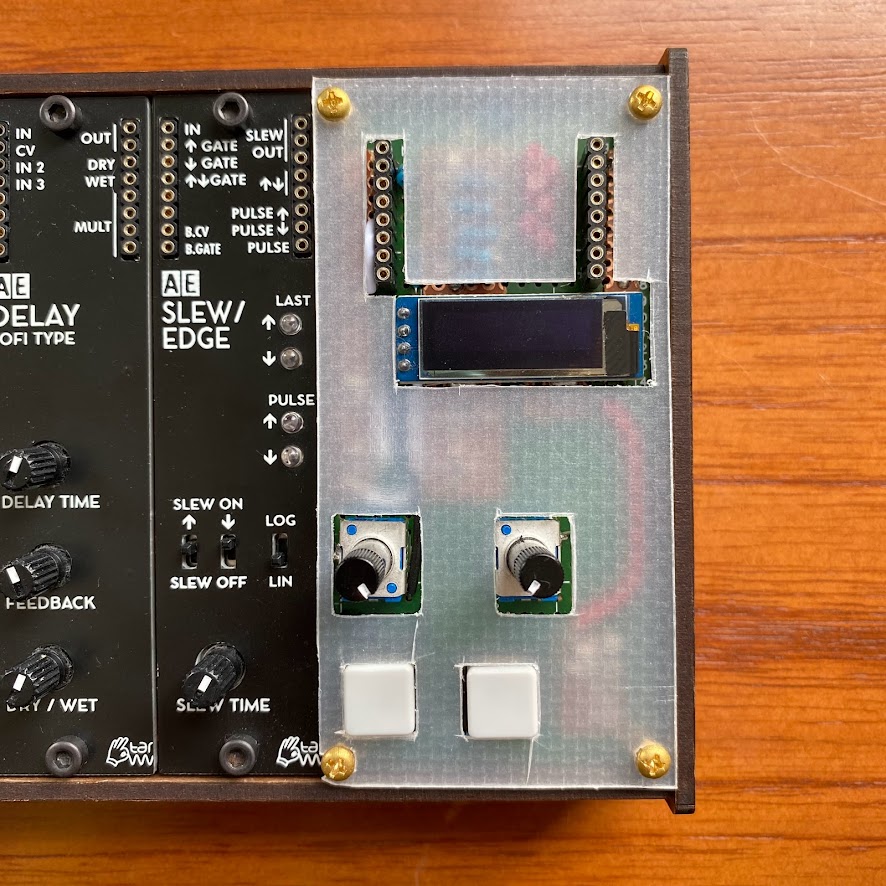

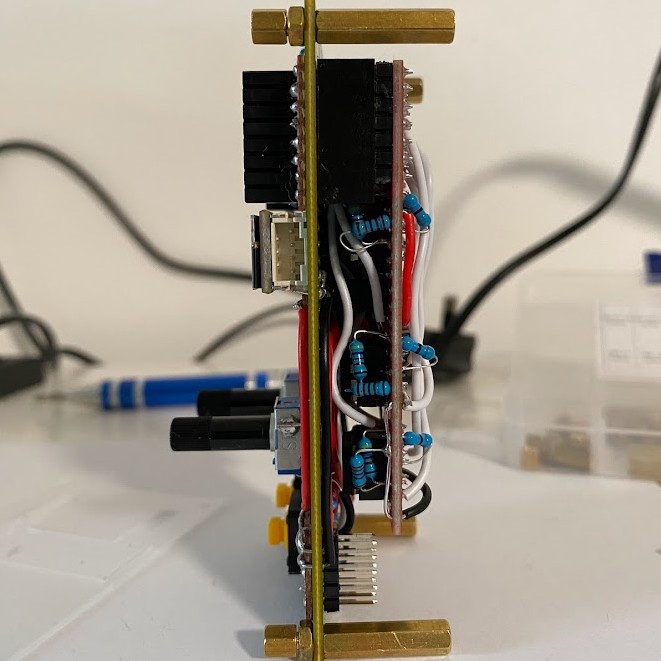

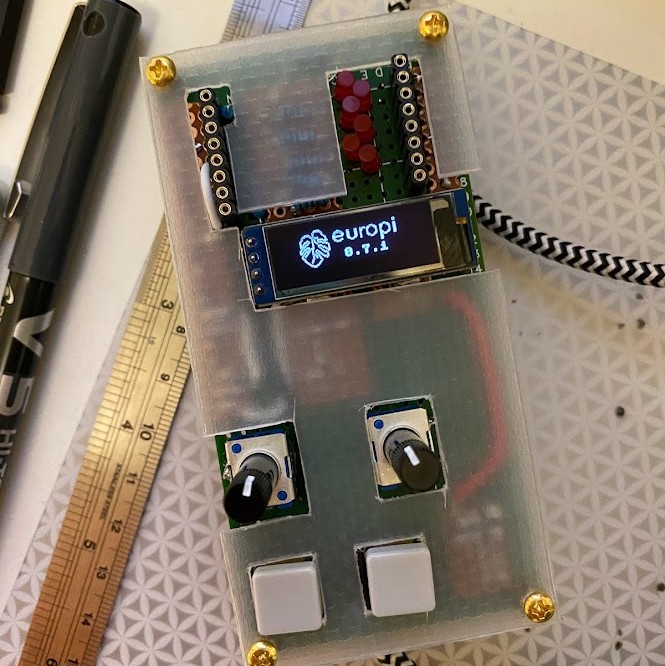

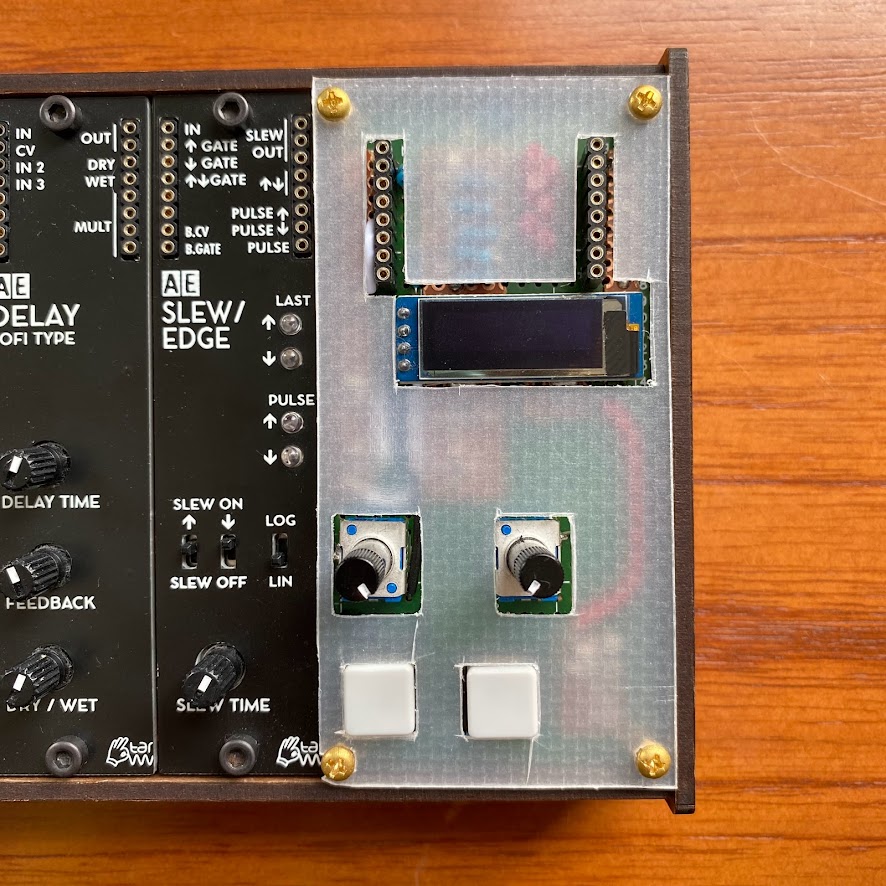

third prototype

optimised the layout again, this one earned a makeshift front panel

everything was working pretty well here, so time to proceed to easyEDA! because of all the wiring underneath this has to sit a little higher in the case than standard TW modules, but i figure a printed PCB will resolve this

problems:

- leds were still weird, so i ended up just scrapping them entirely

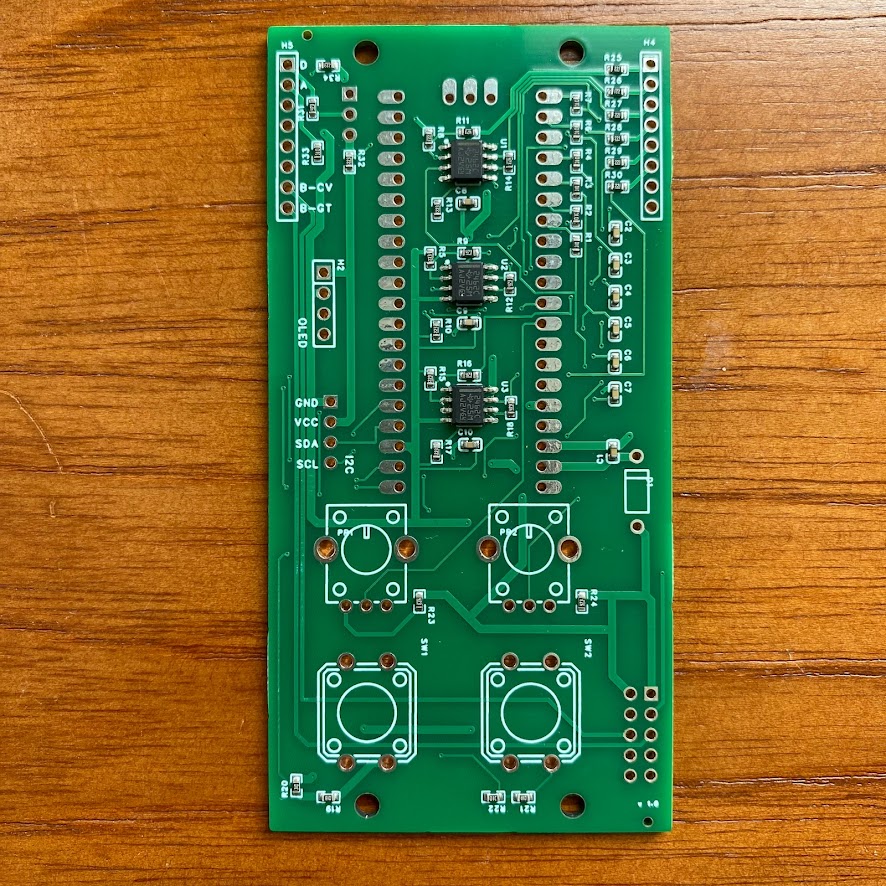

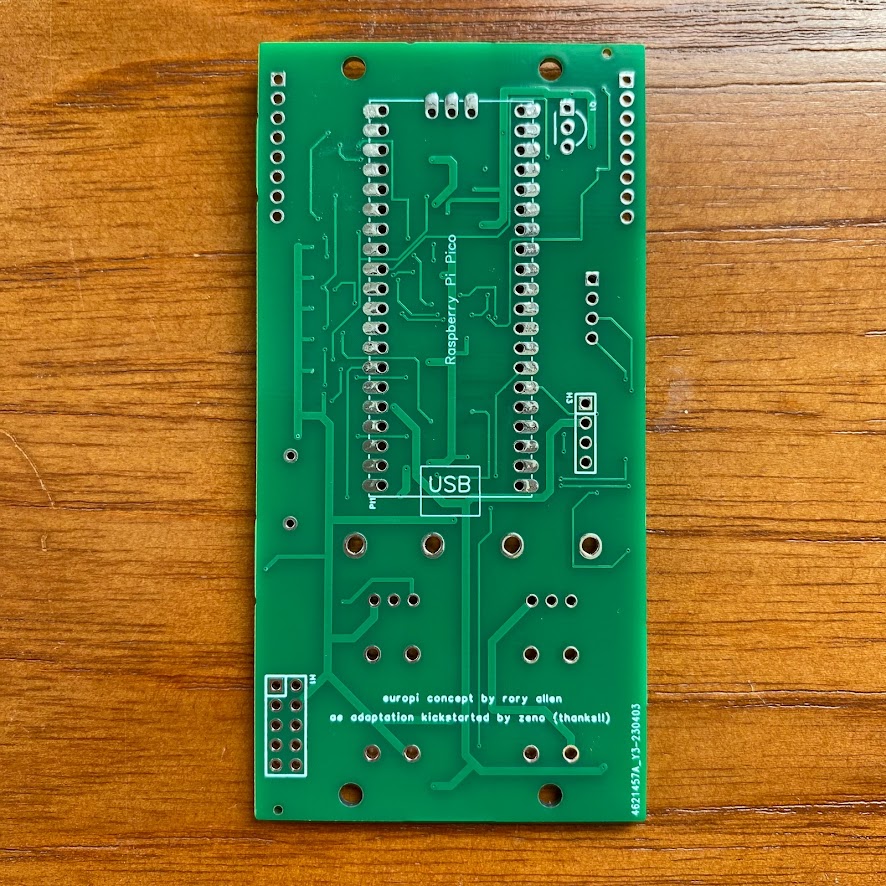

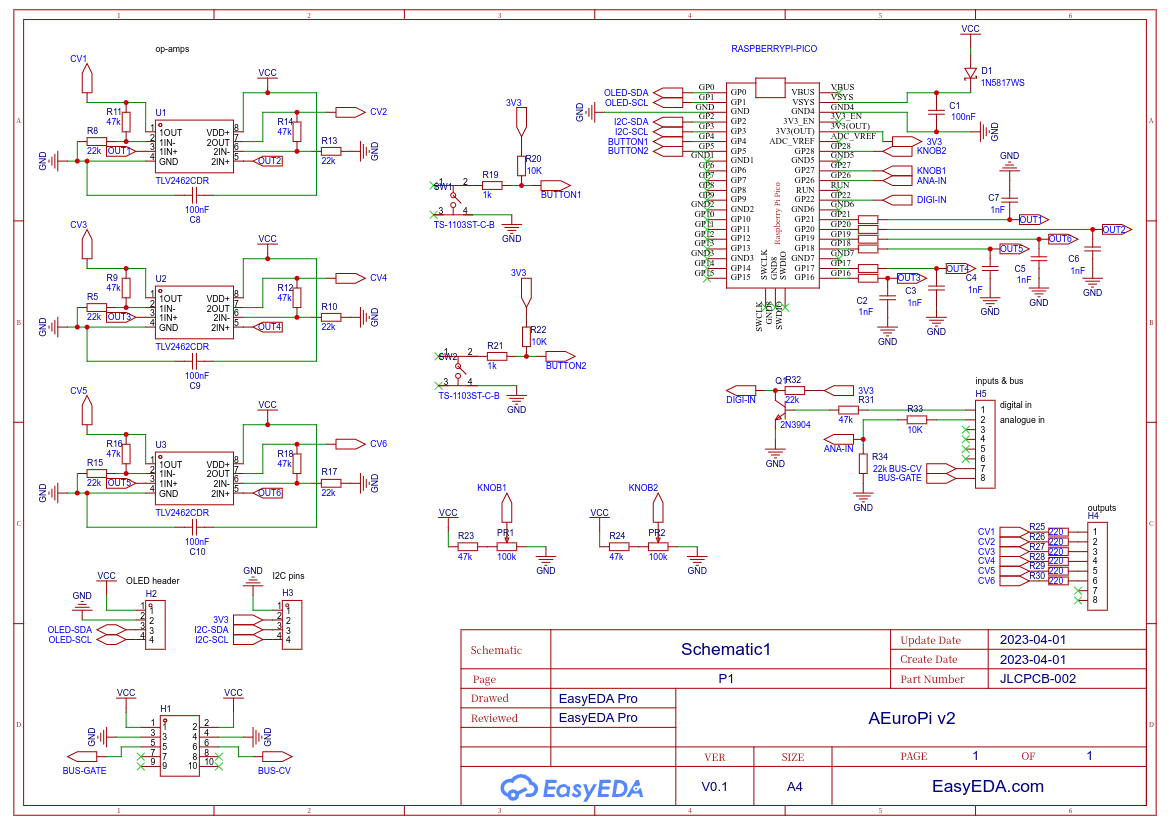

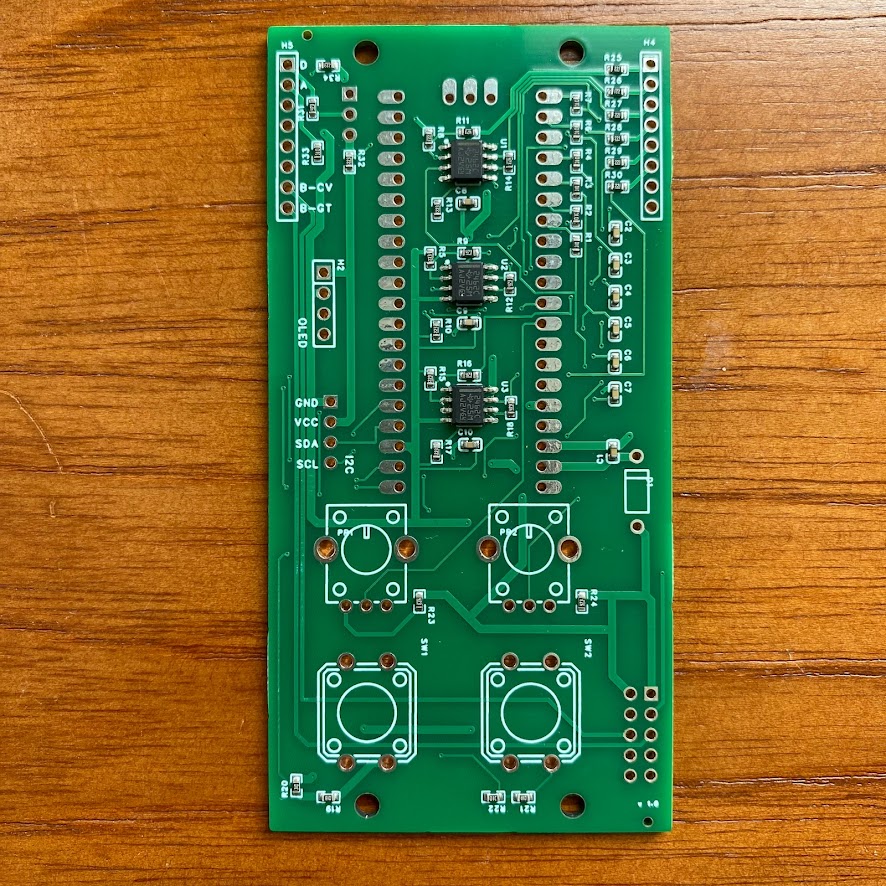

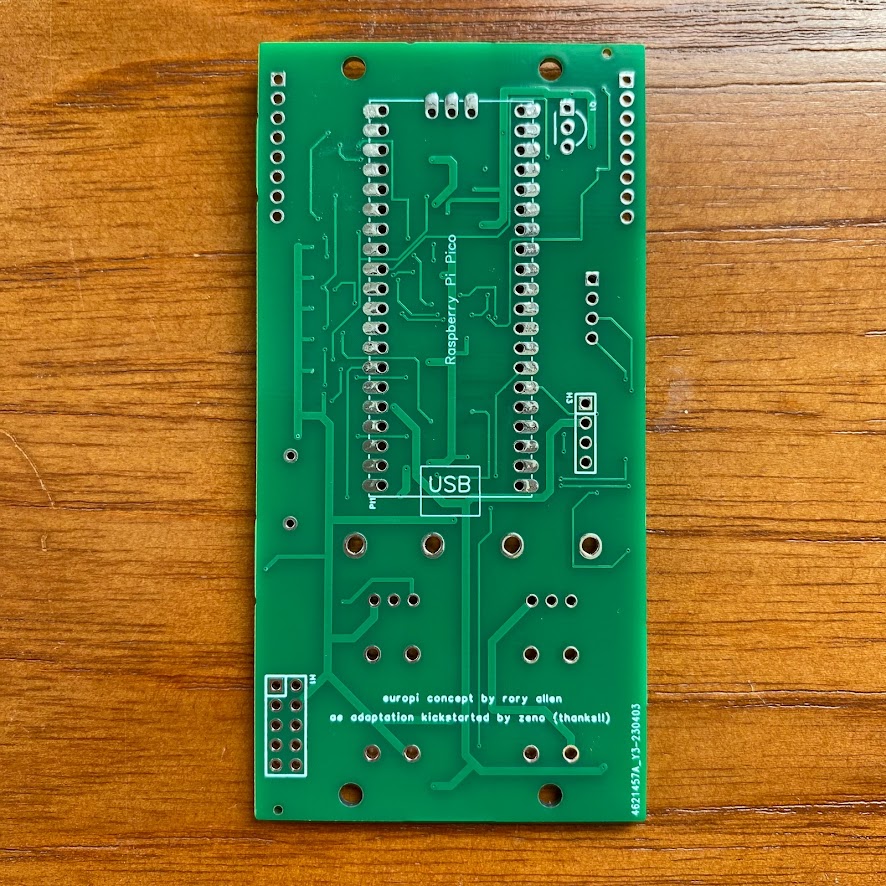

first pcb build

first time pcb making... SMT op-amps saves quite a lot of space. all functions working as expected (after calibration)

want to build your own? gerber files, bom, and pick & place files available here.

putting it all together: build guide

notes:

- removed leds from design entirely

- added an i2c connector on the rear for future expansion (so far untested)

- included midi-cv and gate signals from the bus cable

- added diode on power line to pico to prevent reverse-powering

- (op-amps take power from a separate line so they aren't impacted by voltage drop)

- cap from +5v to gnd before the pico, to smooth out power fluctuations

- changed to round buttons (slightly taller)

- changed to different song huei pots (slightly shorter)

- software: adjusted max voltage value

- software: tweaked pot deadzone

- software: adjusted calibration script for 5v range

- software: customised boot image

having built a few of these now, i can spot a few small amends for future revisions:

- some of the traces run a little close to the board holes, it doesn't seem to be a problem, but might tidy up in future

- i think the 2x5 power pins could stand to be a 1-2mm higher to give the bus cable more wiggle room around the standoffs

- should make the frontpanel holes for the buttons 1mm wider in diameter, so the fit has a bit more tolerance

- frontpanel width is a strict 50mm which leaves a slight gap between modules, should be based on a multiplication of 25.4mm for better fit

- i think the bottom standoff holes should be a fraction lower to align better with the case holes?

- would be nice to have some way of keeping the OLED aligned during soldering

- the i2c pins should probably be 2x4 rather than 1x4

- also not sure if GND > VCC > SDA > SCL is the best order for an i2c connection. there seems to be a bunch of standards

- some of the silkscreen text is a bit small. rory and zeno deserve bigger shoutouts :)